- Auto Parts

- Medical treatment Parts

- Household Parts

- Electron Parts

- Two-tone Parts

- Screw thread Parts

- Metal Parts

- Die-Casting Parts

- Blow Moulding Parts

- other

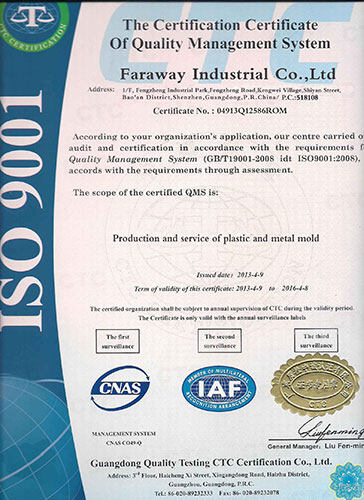

With the rapid development of industrial mold technology, quality is the lifeblood of any enterprise. Only by making the highest quality molds, can we expect to win the trust of our customers. To ensure the quality of our molds, Faraway has developed a complete and scientifically sound system of quality control procedures. From the ordering of the mold materials, to mold design specifications, through parts processing, mold trials, T1 level product inspection and export of the mold, each process has our professional staff utilizing the best professional equipment to inspect the mold's relevant measurements. Each detection result is recorded with a full inspection report. For T1 level products, we review and confirm the product appearance, structure, size, assembly and other related dimensions to be in conformity with customer provided 3D and 2D product drawings and specifications. Faraway works tirelessly to avoid any product non conformity issues that will cause our customers any delays in their production schedules. We have advanced quality testing equipment and professional quality staff, always operating in strict accordance with ISO9001 quality standard to effectively control and improve our quality.

With the rapid development of industrial mold technology, quality is the lifeblood of any enterprise. Only by making the highest quality molds, can we expect to win the trust of our customers. To ensure the quality of our molds, Faraway has developed a complete and scientifically sound system of quality control procedures. From the ordering of the mold materials, to mold design specifications, through parts processing, mold trials, T1 level product inspection and export of the mold, each process has our professional staff utilizing the best professional equipment to inspect the mold's relevant measurements. Each detection result is recorded with a full inspection report. For T1 level products, we review and confirm the product appearance, structure, size, assembly and other related dimensions to be in conformity with customer provided 3D and 2D product drawings and specifications. Faraway works tirelessly to avoid any product non conformity issues that will cause our customers any delays in their production schedules. We have advanced quality testing equipment and professional quality staff, always operating in strict accordance with ISO9001 quality standard to effectively control and improve our quality.

MAIN QC PROCEDURE

1. Mold design control and review.

2. Mold base review

3. Mold steel hardness Inspection.

4. Mold steel dimension measurement

5. Mold Core and Cavity Steel Dimension measurement

6. Mold parts measurement

7. Electrode measurement

8. Mold Pre-Assembly Inspection

9. Products Inspection (FAI, CPK, CMK)

10. Pre-shipment testing (running 2-3 hours in machine)

11. Shipment packaging review

1. Mold design control and review.

2. Mold base review

3. Mold steel hardness Inspection.

4. Mold steel dimension measurement

5. Mold Core and Cavity Steel Dimension measurement

6. Mold parts measurement

7. Electrode measurement

8. Mold Pre-Assembly Inspection

9. Products Inspection (FAI, CPK, CMK)

10. Pre-shipment testing (running 2-3 hours in machine)

11. Shipment packaging review