High requirements of the design to produce high quality molds, has been sticking to our design team in strict accordance with the customer's every request to design the mold.Each part of the mold is according to customer requirements specified spare parts procurement. They are familiar with international standard such as DME, HASCO, RABOURDIN, DAIDO, or customer specific standards. Ensure that each set of tooling is done according to the request of customers, we produce mould can reach any customer's factory for production and very fast simple and rapid tool for maintenance.

High requirements of the design to produce high quality molds, has been sticking to our design team in strict accordance with the customer's every request to design the mold.Each part of the mold is according to customer requirements specified spare parts procurement. They are familiar with international standard such as DME, HASCO, RABOURDIN, DAIDO, or customer specific standards. Ensure that each set of tooling is done according to the request of customers, we produce mould can reach any customer's factory for production and very fast simple and rapid tool for maintenance.When we receive customers provide DXF, DWG, PRT, SAT, IGES, STEP, X - T, after the final product drawing, we will strictly product reviews after each question point. Immediately began to Product feasibility analysis, At the same time with Customer discuss the structure Project management . Once we get feedback from the customer .Designer will start 2d layout and 3 d model design ,once the design is approved by customer,Workshop will proceed to build the mold immediately so that to complete high quality mold in a short period of time.

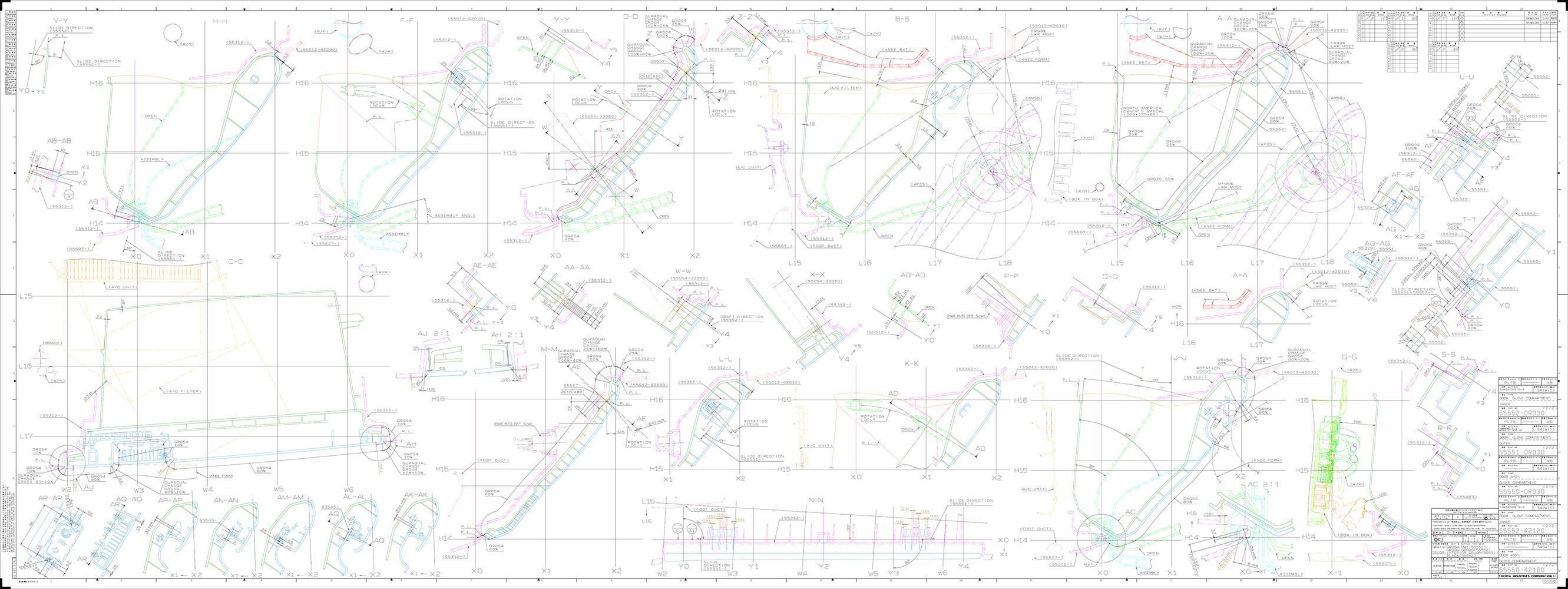

2D Product’s drawing review

We will pay attention to the product on the drawing the tolerance requirements of each assembly position according to the 2 d drawings

Product feasibility analysis

In the product analysis. We treat each customer updated product name record and update into the report . Ensure that the final product drawing is accurate and correct 。At the same time we make a list about cavity number, product shrinkage, color, surface finish, texture, T1 sample quantity, injection molding machine tonnage related information sent to customer confirmation.Ensure each process strictly according to the customers' information for processing.

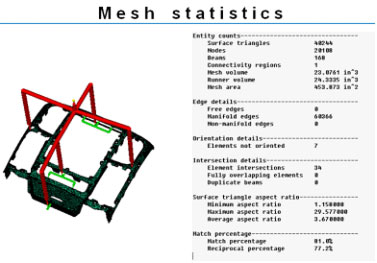

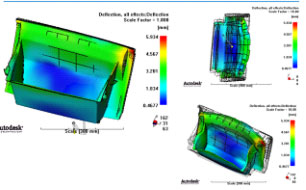

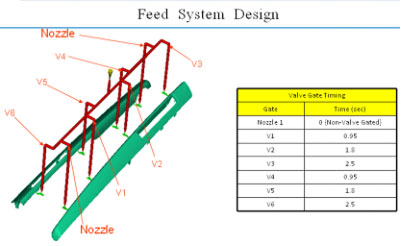

Mold flow analysis

Mold's gate type and size will determine the surface of a product and the production efficienc. For production efficiency and product appearance requirements. Our product information according to the customer to do the professional mold flow analysis. Each gate’s location and size in strict accordance with the mold flow analysis result for execution

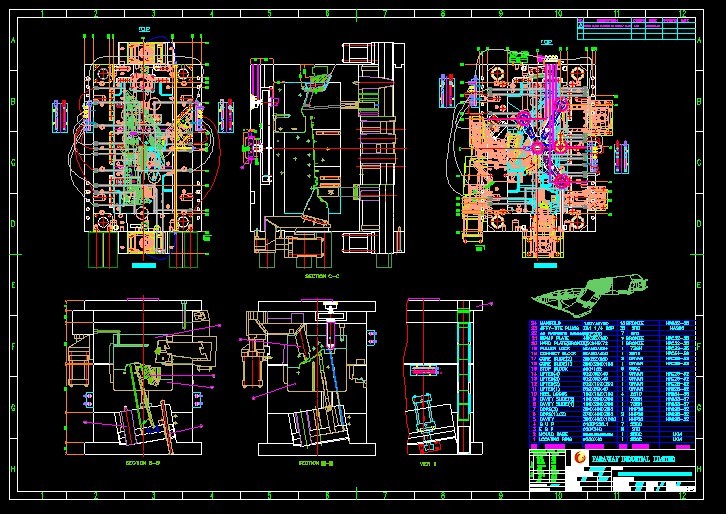

2D Layout

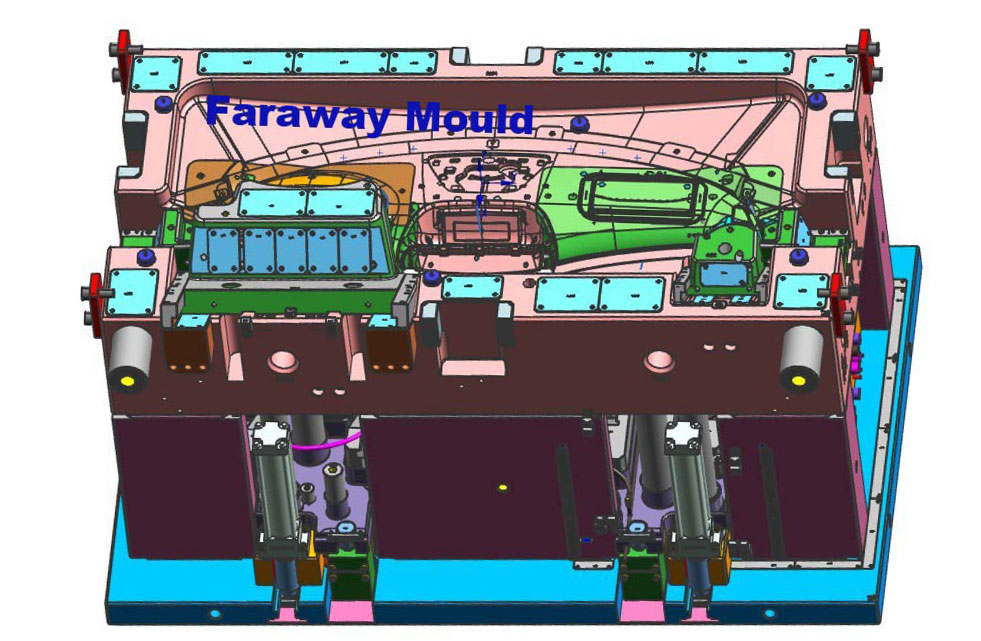

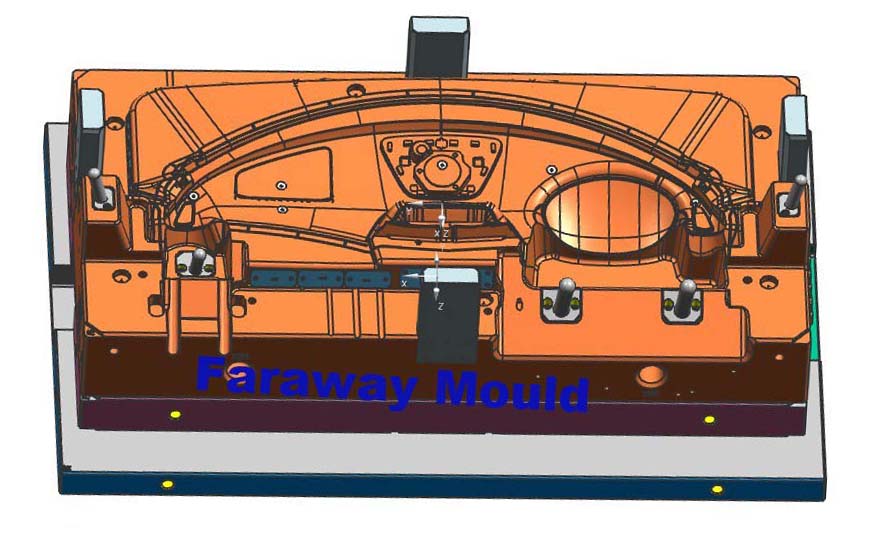

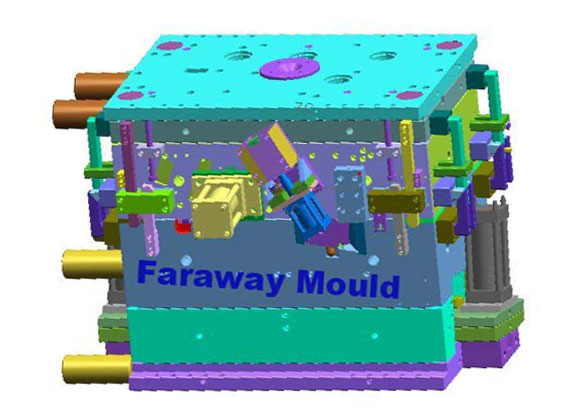

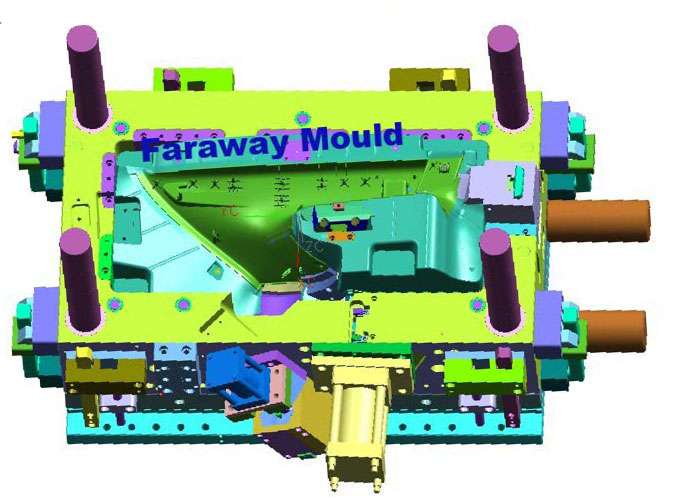

3D Model

Complete 2d and 3d model drawings for mold maintenance is very important,directly related to mold’s life. Even our mold designers in the design of 3 d drawings, must be in strict accordance with the mold of 3 d data to design diagrams, drawings and mold physical consistency